How to Master the Basics of Commercial Wood Framing for Large-Scale Construction Projects

Mastering the basics of commercial wood framing for large-scale construction projects is a fundamental skill that can set a solid foundation (no pun intended!) for any aspiring carpenter or builder. When you're looking to get your hands dirty in the world of construction, it’s crucial to understand that unlike residential framing, commercial projects often demand more robust structures and designs. The scale is just so much bigger! First off, let's talk about the materials. You need to become familiar with various types of lumber and engineered wood products. It's not just about picking up any piece of wood; each has its own characteristics and suitability for different aspects of the frame - so don’t go hammering away at whatever looks good! Also, remember that while cost efficiency is important, skimping on quality could lead to dire consequences. Now, learning how to read and interpret blueprints is like learning another language – but it’s one you've got to speak fluently! Without this knowledge, you’re basically walking blind on site. Blueprints guide us through dimensions, design specifications, and load requirements which are essential when constructing something that needs to stand tall against mother nature's whims.

How to Frame a Wall Like a Professional Carpenter

Tmb studio framing a wall always looks simple and straightforward, but a mistake—like a wall that’s too short or a window opening slightly too small—wastes lots of time and effort later. Here, we’ll show you the basic steps of framing a wall and some simple techniques designed to ensure accurate results. Keep in mind, though, that carpentry practices and jargon vary from region to region and even from one carpenter to the next. Don’t be surprised if some of the labels and marks we show aren’t exactly what you’d encounter on a local building project. No matter where you are in the u. Carpentry is best defined as the art and trade of cutting, working, and joining timber. This makes carpenters perfectly suited for wood framing. Not all carpenters find employment in construction; however, a vast number of them do. Roughly 201,000 carpenters work in the industry, which is 21% of all carpenters in the u. S. Workforce. And, of this number, most will find work as framing contractors. Professional framers, known as framing carpenters , are responsible for building and repairing structures made of wood. While their work on a building may start with that

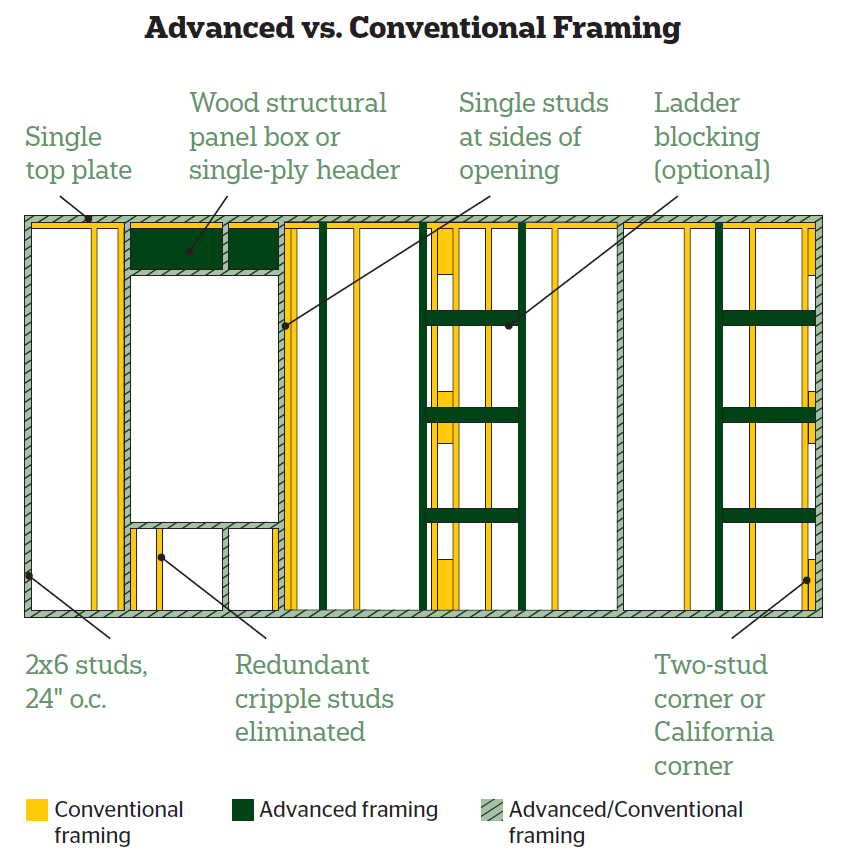

Common Advanced Framing Details

All walls are different. What is common among them is the skill set and tools required. This wall framing article details what you need to know about an interior wall framing layout for applications such as a basement, bathroom, or partition wall. While many of the steps cross over to wall framing for an addition , shed, or three-season room on a deck, i build my interior wall framing piece by piece. Walls framed where there is no ceiling are framed on the “deck” and tipped into place as a unit. If you’re building a wall, the likelihood you need a permit is near 100 percent. There shouldn’t be any issues. That being said, it’s always a good idea to check with your local building department before incorporating changes in a structural assembly. 2x6 framing with 24” oc stud spacing is recognized in the irc and is understood by most code officials. Some less common details, such as single top plates/stacked framing, may not be as well understood by code officials. https://en.wikipedia.org/wiki/Laminated_veneer_lumber Advanced stick framing, also known as optimum value engineering (ove) is a green building technique that optimizes lumber use to improve material efficiency and

What Are Traditional Framing Techniques?

In wall framing, traditional spacing requires a stud each 16 inches. Advanced framing techniques can be employed to increase this distance to 24 inches without sacrificing the structural integrity of the framing. Information on constructing walls with fewer studs can be found in advanced framing: minimum wall studs. The intersections and corners between wall frames can also be improved with advanced framing. At the intersections between interior and exterior walls, traditional framing employs t-posts, which include two studs installed on the exterior wall. The t-post method leaves uninsulated space between the two studs. Advanced framing techniques such as ladder blocking, use of a support post, and use of a connector plate and drywall clips can be employed to eliminate the uninsulated space and improve the overall building envelope. April 4, 2018 / posted in: builders , dealers , framers wood framing is still the dominant technique employed when constructing north american homes. While this is a cost-effective method, designers and builders should keep in mind that with new energy codes there are ways to increase the amount of wall insulation, reduce the amount of lumber used, and reduce thermal bridging with advanced framing techniques. When traditional framing techniques are followed, insulation

Structural integrity, energy efficiency, waste reduction: the advantages of advanced framing.

Advanced framing techniques, sometimes referred to as optimum value engineering (ove), optimize material usage to increase the energy efficiency of the structure and reduce the amount of waste generated in the construction process. Advanced framing uses less lumber to build homes that can accommodate more insulation with a much higher r-value, while still remaining structurally sound. In fact, in most cases, advanced framing techniques use about 25-30% less lumber in the frame, which leaves room for more insulation and a more energy-efficient home. The main component of advanced framing techniques is to only use lumber where it’s needed to maintain structural integrity. As the construction industry evolves, so too do framing systems. Innovative techniques and technologies have revolutionized the way wood framing is approached, offering enhanced efficiency, sustainability, and structural integrity. Advanced framing systems optimize material usage, minimize waste, and improve energy efficiency, aligning with the industry’s growing emphasis on sustainability and green building practices. From prefabricated framing components to modular construction methods, the landscape of framing systems is undergoing a paradigm shift. These innovations not only streamline the construction process but also pave the way for greater creativity and customization in architectural design. https://en.wikipedia.org/wiki/Glued_laminated_timber Advanced